Now in a brand new 30,000 sq. ft. facility. Same trusted service, greater capacity to support your next breakthrough.

CDMO Medical Devices

Smarter, faster manufacturing for high-performance medical products

You’re building something that has to work every time, in every hand, for every patient. Sonele brings your bold ideas to market faster, smarter, and with less risk.

90%

Projects include direct design and engineering input

<8 Weeks

Average turnaround for first-article prototypes

10-1K+/month

Flexible and scalable production capacity for complex builds

50+

Countries where client devices are in use today

Let’s create the device you’ve always envisioned.

You’ve put in the work to design a high-performing medical device. Now it’s time to build it with a partner who can match your standards.

Sonele brings technical depth, precision execution, and a process built around your product goals. Whether you’re producing your first clinical units or preparing for large-scale runs, we help bring your CDMO medical devices to life with clarity, confidence, and control from our 30,000 sq. ft. facility built specifically for medical device manufacturing.

Chris Bass, CEO

InventoRR MD

“It has been great working with Sonele. Their team has been extremely responsive and helpful in working with us to design AbClo into the great product it is today.”

A better partner for CDMO services

Lower risk at every step

Our engineers contribute early to refine designs, materials, tolerances, and processes so your build moves forward without unexpected setbacks.

Engineers in your corner

Your product benefits from a team that understands your technical goals and the production-level precision needed to meet them.

Built for close collaboration

You’ll work directly with experienced engineers backed by in-house capabilities that keep timelines tight and quality consistent.

Focused on MedTech quality

We meet the demands of clinical and commercial production with strict quality control, full traceability, and a deep understanding of what’s at stake.

How our end-to-end contract development and manufacturing approach brings your device to life

Automated test and inspection

In-house acoustic, mechanical, and electrical test platforms with integrated software. Some of our capabilities include mechanical failure testing, thermal cycling, high-potential (hi-pot) and patient leakage tests, custom test scripts with matching fixtures, and full regulatory safety compliance — all with complete traceability and data logging.

Epoxy and adhesive handling

Controlled dispensing of high-performance adhesives with UV, thermal, and dual-cure workflows optimized for structural integrity, electrical reliability, biocompatibility, and repeated sterilization.

Full-system electromechanical integration

Turnkey assembly and testing of complete medical devices, including sensors, PCBs, displays, batteries, motors, and wireless modules, with custom enclosures, sterile/non-sterile packaging, and product labeling.

Custom tooling and fixturing

Design and fabrication of precision assembly and test fixtures tailored to each product’s geometry and production requirements.

Simulation and tolerance analysis

Finite Element Analysis (FEA) and tolerance analysis are applied early to validate performance and manufacturability before the first prototype is built.

Ultrasound transducer and stack expertise

Specialized OEM supply and integration of our single-element, linear, and 2D ultrasound arrays with deep experience in acoustic stack design and performance.

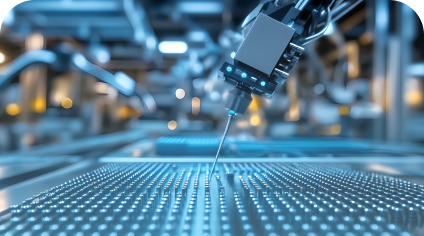

High-precision microfabrication

Micron-level machining, lapping, grinding, dicing, and 3D laser micromachining for intricate geometries and tight-tolerance components.

How our end-to-end contract development and manufacturing approach brings your device to life

R&D + Proof of Concept

De-risk early-stage development with expert feasibility studies, technology validation, and innovative solutions.

- Our medical product developers help you identify technical challenges early, reducing costly rework later in the process.

- We provide data-driven insights to refine product concepts before you commit to full-scale development.

Medical Device Prototyping

Accelerate design iteration and validation through high-fidelity functional prototypes.

- We enable real-world testing of form, function, and performance before finalizing the design.

- We provide quick-turnaround prototypes for stakeholder feedback and investor presentations.

Electrical & Mechanical Engineering

Optimize mechanical design and electrical systems for reliability, manufacturability, and performance.

- Our engineering team ensures seamless integration of components, reducing potential failures in production.

- Our designs are optimized for scalability, efficiency, and cost-effectiveness.

Software & Firmware Development

Ensure seamless device operation, data processing, and connectivity with embedded software and firmware.

- We provide custom real-time software solutions tailored for medical devices, ensuring precision control and regulatory compliance.

- We integrate wireless connectivity, AI-driven diagnostics, and cloud-based data solutions where needed.

Industrial Design

Design ergonomic, user-friendly, and aesthetically refined devices optimized for clinical and patient use.

- Our medical device designers focus on human factors engineering to enhance ease of use and safety.

- We ensure every medical device design meets market expectations and usability standards, improving adoption rates.

Regulatory Support

Reduce regulatory roadblocks and streamline your path to market approval.

- We can offer assistance in navigating the correct testing protocols to meet the required regulatory approvals (i.e. FDA, Health Canada, CE Mark).

- We provide detailed design history files, process validation reports, risk assessments, and testing documentation to facilitate your regulatory submissions.

- We maintain rigorous quality and traceability standards throughout development and production to ensure compliance with regulatory (i.e. FDA, Health Canada, CE Marking) requirements.

Component Fabrication

Get tighter control over quality, performance, and cost, avoiding inconsistencies from third-party suppliers.

- We manufacture critical components in-house or work with trusted suppliers to ensure reliability and compliance.

- Our high-precision, high-quality fabrication processes are tailored to medical device requirements.

Supply Chain Management

Avoid supply chain disruptions, material shortages, and unexpected costs, ensuring smooth production scaling.

- We manage vendor relationships, procurement, and inventory to ensure on-time availability of high-quality materials.

Process Validation

Gain confidence in consistent product performance and regulatory compliance from the start.

- We conduct detailed process validation (IQ, OQ, PQ) to guarantee that every step meets regulatory and quality standards.

- We guarantee repeatable and reliable manufacturing processes.

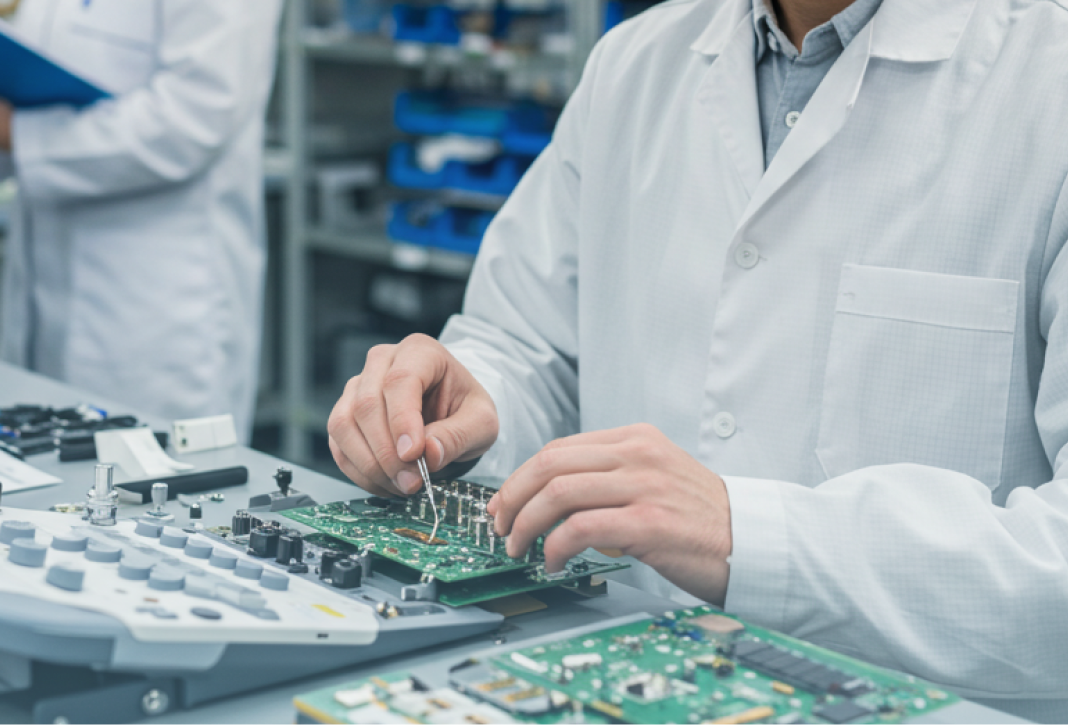

Device Assembly & Testing

Ensure precision assembly with rigorous quality control and testing.

- Our controlled manufacturing environments ensure high-quality assembly, meeting strict ISO 13485 and FDA guidelines.

- Every device undergoes functional and performance testing to verify compliance with specifications before release.

Packaging & Labeling

Receive ready-to-ship devices in compliant packaging, reducing post-manufacturing processing time.

- We ensure packaging materials, sterilization compatibility, and labeling meet global regulatory standards (FDA, CE, MDR, etc.).

Sterilization Management

Avoid complex sterilization logistics while ensuring compliance with sterility assurance level (SAL) requirements.

- We coordinate sterilization processes (i.e. ETO, gamma, e-beam, or steam sterilization) with qualified partners and manage process validation.

Stocking & Distribution

Reduce inventory holding costs, lead times, and supply chain risks, allowing for faster market response.

- We offer stocking, warehousing, and delivery, ensuring devices are available when needed.

Frequently asked questions

Earlier than you think. Involving a contract development and manufacturing partner during the initial concept or early rapid prototyping phase helps prevent design issues, reduce downstream risk, and accelerate your path to market launch. Our interdisciplinary teams offer a proactive approach that connects design, engineering, and manufacturing from day one.

Yes. Our team works closely with yours on DFM, tolerance analysis, and material selection to identify and address potential risks early in the product lifecycle. This collaborative approach improves quality, reduces the risk of product recalls, and ensures your device meets regulatory compliance requirements. It’s part of how we integrate contract development into a complete, comprehensive solution.

Absolutely. We specialize in high-mix, mid- to high-volume contract manufacturing, supporting everything from early feasibility builds to clinical units and full commercial production. Our manufacturing organization is equipped to evolve with your product, ensuring consistency and quality through every phase.

We manufacture a wide range of complex systems for the medical device industry, including:

- Surgical & Interventional Devices

- Diagnostic Systems

- Medical Consoles & Instrumentation

- Wearables & Wireless Devices

- Robotic & Mechatronic Systems

Our strengths lie in building complex components to tight tolerances, integrating advanced technologies, and delivering high-performance assemblies that support the full product lifecycle.

Yes. Our CDMO device manufacturing services include procurement, inventory management, supplier coordination, and global logistics, so your team can focus on R&D and clinical strategy. Our development and manufacturing teams streamline handoffs and reduce operational friction, allowing for greater agility and cost efficiency as you scale.

We follow robust quality control protocols, maintain fully traceable documentation, and align with ISO 13485 principles. Our understanding of regulatory affairs and regulatory challenges means we help your product meet global standards for patient safety, even in complex, multi-step manufacturing processes. We take pride in our specialized expertise and commitment to excellence.

Yes. Whether you’re preparing for clinical trials or scaling up for commercial launch, Sonele’s end-to-end CDMO services support your entire journey. Our 30,000 sq. ft. facility and scalable core competencies enable us to transition from pilot runs to high-volume production while maintaining quality, compliance, and flexibility.

Contact Us

Ready to push the boundaries of medical technology?

The future of healthcare innovation starts here.

Fill out the form, and we will contact you within 3-5 days to start the process of bringing your breakthrough technology to life.